Precision guide bushings 62HRC Non - standard Customize for Press die components

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Precision guide bushings 62HRC Non - standard Customize for Press die components <

Precision guide bushings 62HRC Non - standard Customize for Press die components

1. Material

SUJ2 ( 52100 )( 1.2067 ) equivalent

20Cr ( 5120 ) ( 20Cr4 ) ( SCr435 ) equivalent

2. Hardness

58 HRC ~ 62 HRC

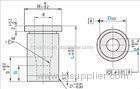

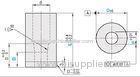

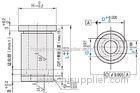

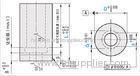

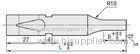

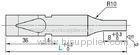

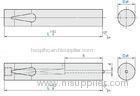

3. Specifications

- Standards : MISIMI / DIN / AISI etc.

- Mounting method flange fixing

- Further dimensions, lengths and materials available on request

- Customized sizes are accepted

- Service: OEM available , and standard with stock

- Tolerance : press-fit part: m5, sliding part:-0.001 ~ -0.005mm, Head : - 0.2 ~ - 0.1mm

- Diameter arrage : Φ 8.0mm ~ Φ 120 mm or according to customer’s demand .

- Polishing: can make close to Ra 0.4 standard is R0.8

- Good-quality and precision

- Nitrogen treatment to improve the hardness

- More products can be produced according to PUNCH / DANLY / DME / HASCO / TOHATSU / FIBRO / AGATHON / STRACK / PEDROTTI / RAYMOND / FUTABA / SANKYO / PROGRESSIVE / RABOURDIN , etc.

4. Machinery & Equipments

- CNC machining center; CNC lathe; Normal lathe; CNC milling machine;

- General punching machine, CNC turning center; Wire EDM, etc.

- And we also can offer 4 or 5 axis-CNC center processes.

- General milling machine; General drilling machine; General planning and grinding machine

5. Application

Leader components ,used in conjunction with the guide pillars

- Plastic injection mold components

- Press die components

6 . Machinery & Equipments

- CNC machining center; CNC lathe; Normal lathe; CNC milling machine;

- General punching machine, CNC turning center; Wire EDM, etc.

- And we also can offer 4 or 5 axis-CNC center processes.

- General milling machine; General drilling machine; General planning and grinding machine

7. Further Information

|

Testing |

Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, |

|

QC |

1) Technicians self-check in production |

|

Main Markets |

North America, South America, Eastern Europe , West Europe , North Europe, China HSS Punches Online Market. [China (Mainland)]

Business Type:Manufacturer |